Resin printers have become a popular choice for 3D printing enthusiasts who want to create highly detailed and intricate objects. Resin printing is a process that uses UV light to harden liquid resin, layer by layer, until the desired object is formed. There are different types of resin printers available on the market, each with their own strengths and weaknesses. In this post, we will delve into the different types of resin printers available, including SLA, DLP, and MSLA printers.

SLA (Stereolithography) printers are the oldest type of resin printers. They use a laser to harden the resin and create the object layer by layer. SLA printers can produce highly detailed objects with a smooth finish. However, they are slower than other types of printers and require a lot of maintenance.

DLP (Digital Light Processing) printers use a digital projector to shine a light onto a vat of liquid resin, hardening it layer by layer. DLP printers can create objects quickly and with high accuracy. They can also print multiple objects at once, which is a great advantage for mass production. However, the objects produced by DLP printers may have a rough surface finish.

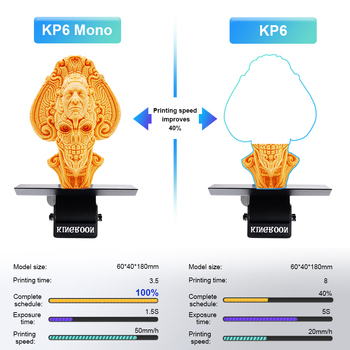

MSLA (LCD-based Stereolithography) printers are a newer type of resin printer that use an LCD screen to project the UV light and harden the resin layer by layer. MSLA printers are faster than SLA printers and produce smoother objects than DLP printers. They also have lower maintenance requirements than SLA printers. However, MSLA printers may have more limited build volume compared to DLP printers.

When choosing a resin printer, it is important to consider the type of object you want to create, the level of detail you require, and your budget. Each type of printer has its own strengths and weaknesses, so it is important to do your research and choose the right one for your needs.

Here are some factors to consider when choosing a resin 3D printer for beginners:

- Price: Resin 3D printers can vary in price, with some models costing several thousand dollars while others are more affordable. For beginners, it’s generally recommended to start with a more budget-friendly option until they have gained more experience and have a better understanding of their specific needs.

- Ease of use: Some resin 3D printers can be more complicated to use than others, with more advanced features and settings. For beginners, it’s often recommended to choose a printer with a simple interface and user-friendly software.

- Build volume: The build volume of a printer determines the maximum size of the objects that can be printed. Beginners may not need a large build volume, but it’s important to choose a printer that is suitable for the specific types of projects they are interested in.

- Customer support: It’s important to choose a resin 3D printer from a reputable manufacturer that offers good customer support, as beginners may have more questions or need assistance getting started.

Based on these factors, some popular resin 3D printers for beginners include the Anycubic Photon, Elegoo Mars, Creality LD-002R, and Phrozen Sonic Mini. These printers are affordable, user-friendly, and offer good quality prints for their price range.

- Zortrax – Provides high-quality and reliable resin printers for professionals and businesses.

- Elegoo: Elegoo is a popular brand known for their affordable, high-quality resin for 3D printing. They offer a variety of colors and types of resin for different applications.

- Anycubic: Anycubic is another well-known brand in the 3D printing industry, offering a range of high-quality resins for their own line of 3D printers as well as other popular models.

- Siraya Tech: Siraya Tech is a premium brand that specializes in high-performance resins for 3D printing. Their products are known for their strength and durability, making them a popular choice for functional prototypes and production parts.

- Monocure 3D: Monocure 3D is an Australian company that produces high-quality resins for 3D printing, including their popular Rapid and Standard resins.

- Nova3D: Nova3D is a Chinese manufacturer of 3D printers and resins, offering a variety of colors and types of resin for different applications.

- MatterHackers is a 3D printing and digital manufacturing company that offers a range of 3D printing supplies, including resin. Their selection includes a variety of colors and finishes from top brands.

- 3D Universe is a retailer that offers a range of 3D printing products, including printers, filaments, and resins. They carry resins from well-known brands like Formlabs, Elegoo, and Monocure.

- Printed Solid is a 3D printing company that offers a range of products for 3D printing enthusiasts. Their selection of resins includes standard resins, flexible resins, and specialty resins for specific applications.

- MakerBot is a leading manufacturer of 3D printers and related accessories. They offer a variety of resins for use with their printers, including standard resins, tough resins, and specialty resins for specific applications. Their resins are designed to work seamlessly with MakerBot printers for optimal performance.

In conclusion, resin printing is a great way to create highly detailed and intricate objects. Each type of printer has its own strengths and weaknesses, so it is important to choose the right one for your needs. By doing your research and selecting the right type of resin printer, you can unlock your creativity and bring your ideas to life.